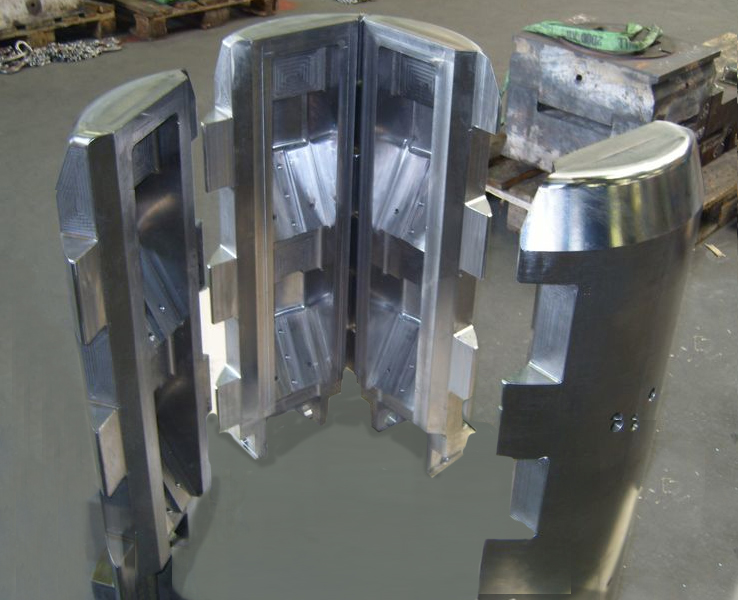

We are absolute specialists in 5-axis-milling of gears. As the technology leader in this sector, we continually improve our know-how, creating innovative solutions for our customers. Read more ….

Major benefits at a glance:

- maximum degrees of freedom in design of gearing:

- double helical and herringbone gearing, asymmetric tooth forms, etc.

- interfering contours are no longer a problem

- hardly any restrictions in contact pattern modification

- any desired special materials

- production on universal milling machines with standard tools

- soft and hard machining (to 62 HRC) on one machine

- high level of flexibility and very short lead times

Services we provide:

We will of course gear your components according to your specifications – however, we also offer complete production incl. materials, turning and milling as well as case-hardening or alternatively nitrifying. We produce from module 5 to large module gears up to a maximum tip diameter of 2000 mm (larger diameters upon request).

Gearing technology

Gearing technology