… more than just an extended work bench:

Supported by a pool of highly specialised partners, we offer you a full service, satisfying every possible requirement. Our company will of course take over project management, process responsibilities and quality assurance.

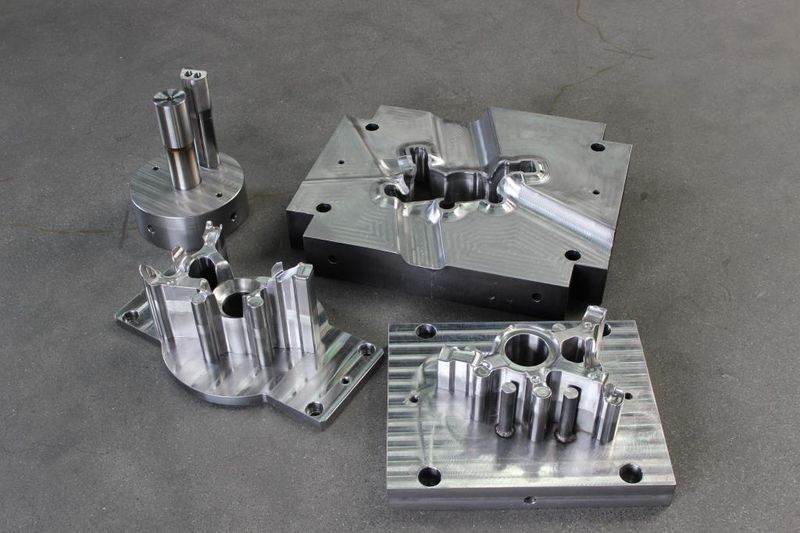

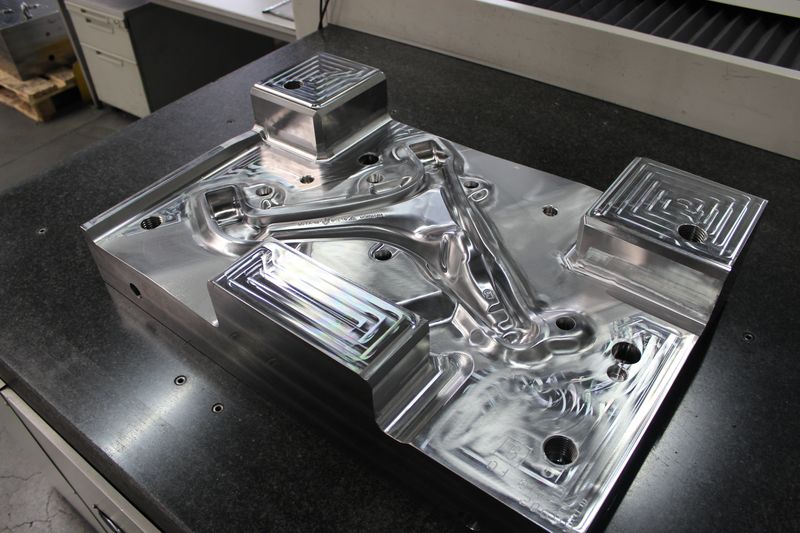

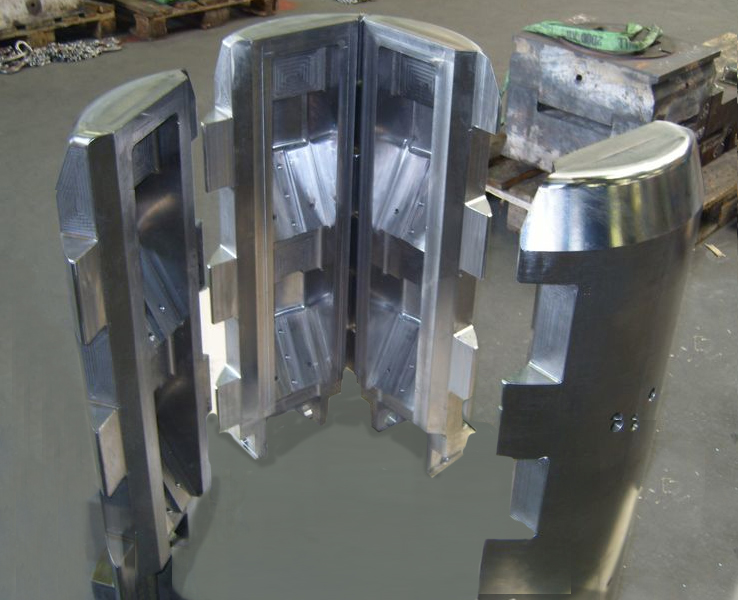

process design forming technology

• multiple stage forging processes steel, aluminium, NE alloy

• forging rolls and cross wedge rolls

• tool design

• process support, running-in of processes on site

optical scanning + Re-Engineering

• optical digitalising and measuring of complex moulds and components

• reverse engineering – upon request incl. topological surface structure

welding

• repairs

• increasing tool life for forging tools with load adapted multiple material component systems

provision of raw materials

• tool steels

• engineering steels

• case-hardened steels

• stainless steels

• high temperature resistant special alloys

• other incl. all necessary testing certificates, as well as MT an UT testing

heat treatment / coating

• tempering / hardening

• case-hardening / surface hardening

• short- / long-term nitrifying

• salt bath nitriding / nitrocarburizing

• PVD, PACVD, multi-layering

others

• grinding

• wire-cut EDM and much more

collection and delivery service

• fast

• reliable

• uncomplicated