Gear repairs

… unexpected need for spare parts – sudden system shutdown ?

…. delivery times for original spare parts too long ?

…. technical documentation no longer existent ?

We have the right solutions for your requirements, with fast delivery times:

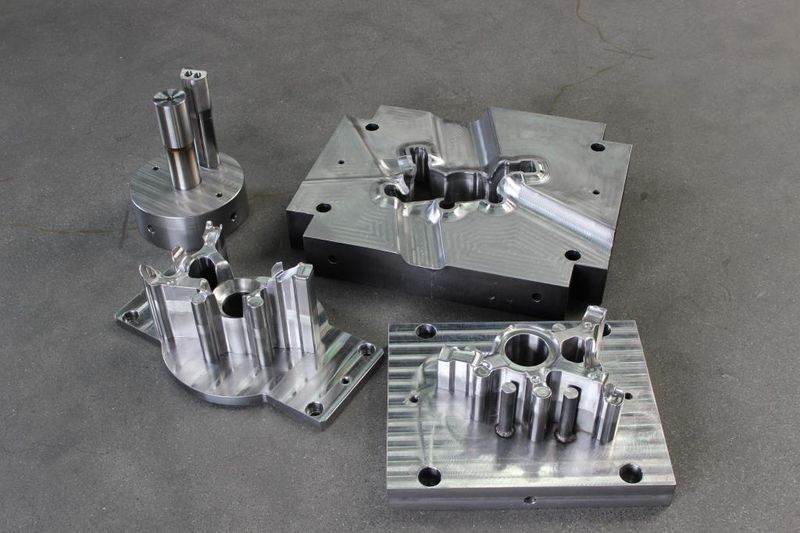

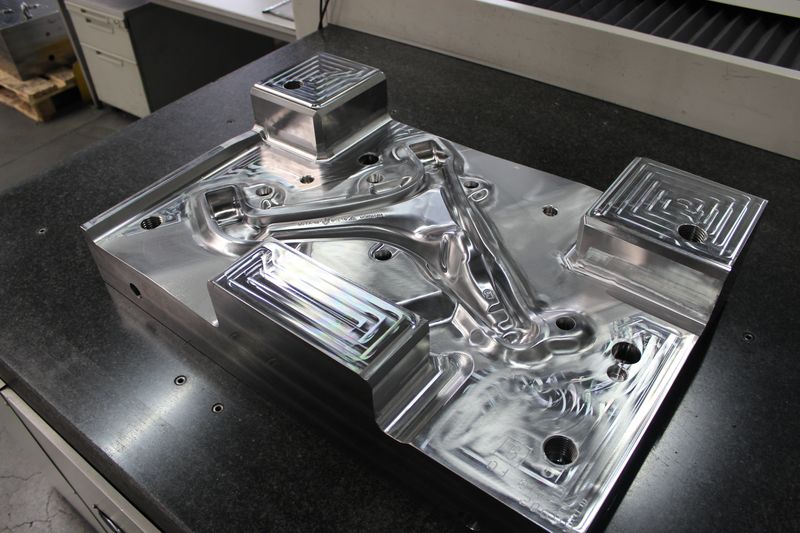

- spare parts production with very short delivery times

(dependent of availability of raw materials) - repair of large gear wheels using ring inserts

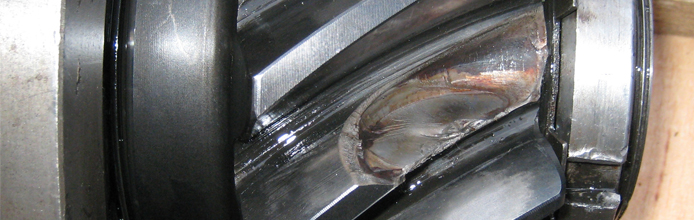

- expert repair welding

(according to extent of damage – as a fast interim solution)

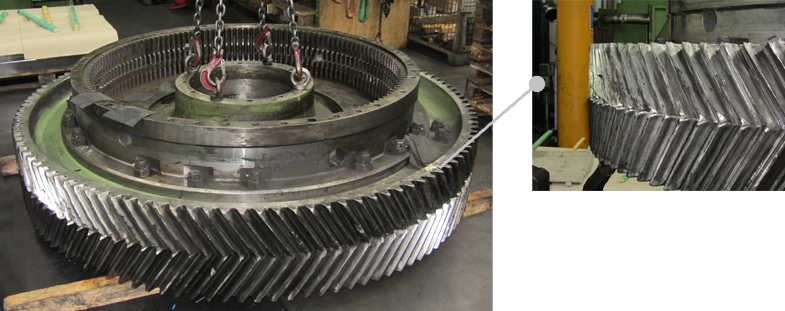

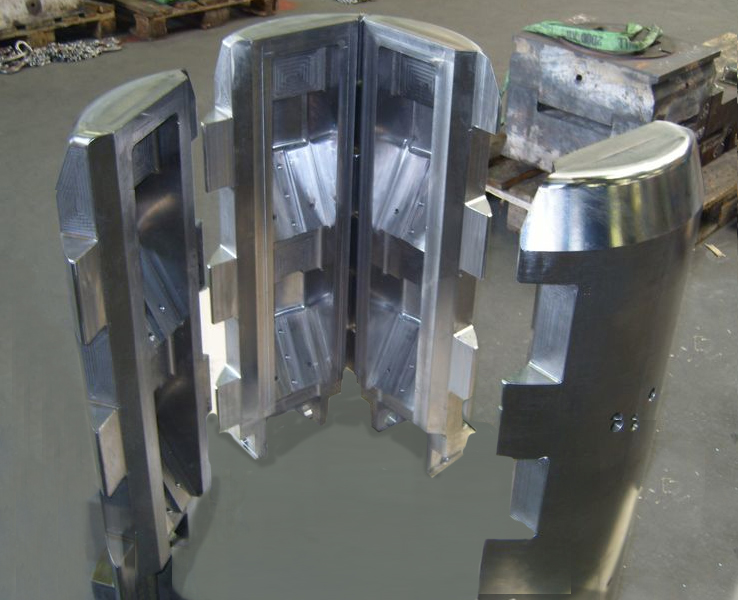

Example of application:

- repair using ring insert

- large gear wheel from press drive

- m= 18, z= 120, Da= 2438 mm, b= 400 mm

Procedure:

- measurement of center distance (on site) and

- determination of gearing parameters

- design of repair gearing bandage

- raw material procurement: rolled ring made of 42CrMo4

- turn off defective gearing – machining seat contour for repair insert

- manufacture of the bandage ring and assembly on the wheel body

- machining of gearing on a 5-axis-milling machine

- spare part production of corresponding pinion (raw material procurement, turning, 5-axis-milling of gearing)

➦ typical lead time (according to availability of materials)

- pinion (Da < 600 mm): 1 – 2 weeks

- wheels (Da < 2000 mm): 8 – 10 weeks

➦ Implementing a gearing bandage is a long-term repair solution !