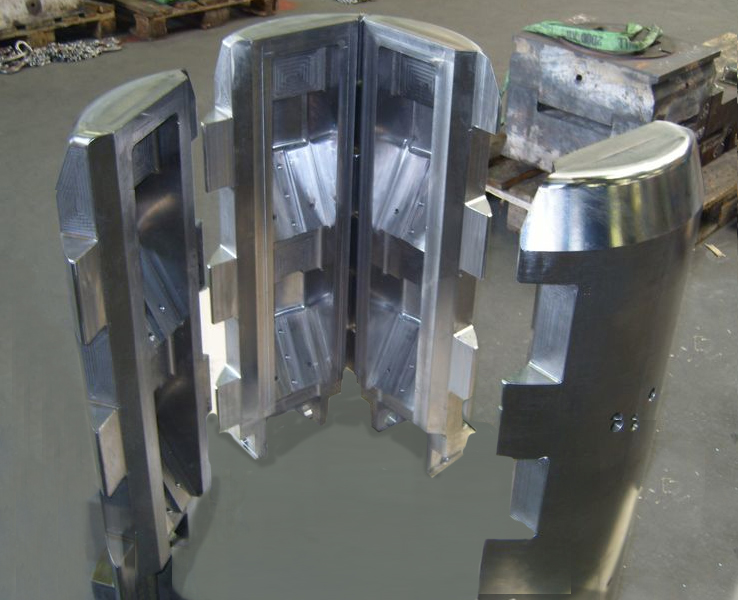

- modules of 5 to 50 and more

- manufacturing in special materials

- almost no limitations for interfering contours

- unconventional gear profiles (e.g. asymmetric)

- practically no restrictions on tooth profile design

(root and tip relief, crowning) - protuberance milling after hardening to produce constant grinding allowance

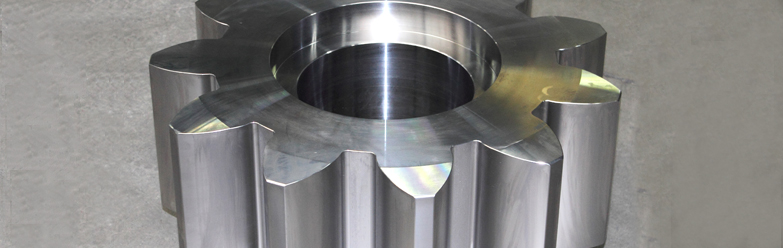

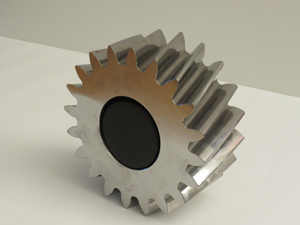

Pinion:

Pinion:

| Material: | 42CrMo4 |

| Da: | 185 mm |

| m: | 8 |

| z: | 20 |

| ß: | 16° |

| b: | 80 mm |

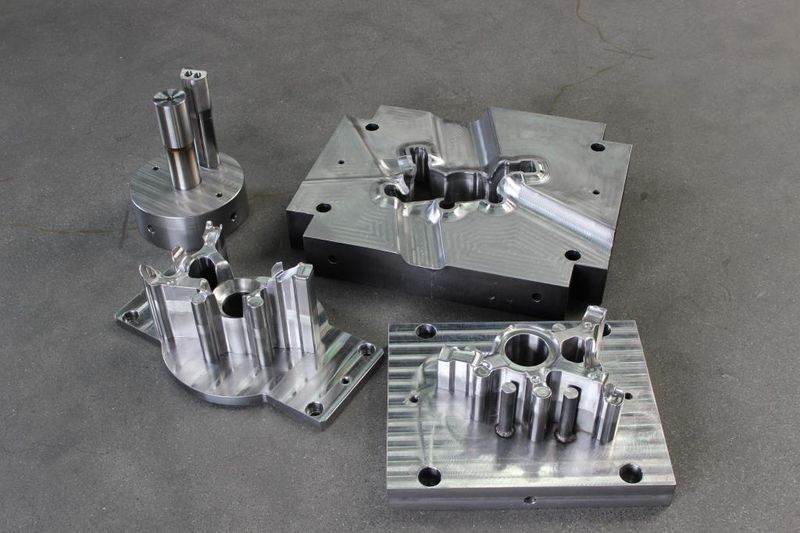

Pinion:

Pinion:

lantern pinion gearing

| Material: | 30CrNiMo8 |

| Da: | 655 mm |

| m: | 48 |

| z: | 11 |

| b: | 250 mm |

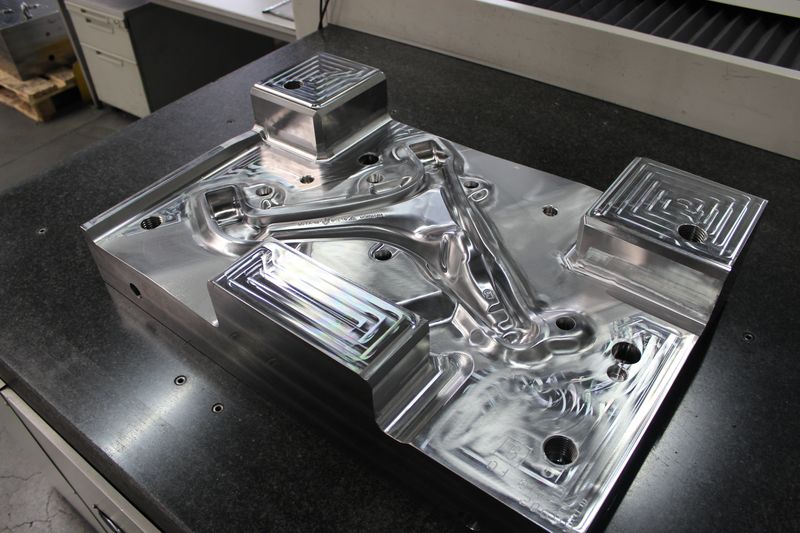

Pinion Shaft:

Pinion Shaft:

| Material: | 18CrNiMo6-7 |

| Da: | 560 mm |

| m: | 27 |

| z: | 17 |

| ß: | 11° |

| b: | 400 mm |

production sequence:

• pre-milling

• milling protuberance

• case-hardening

• pre-milling to a constant allowance

• grinding